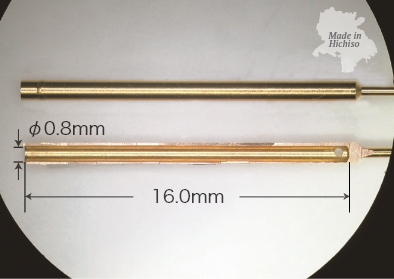

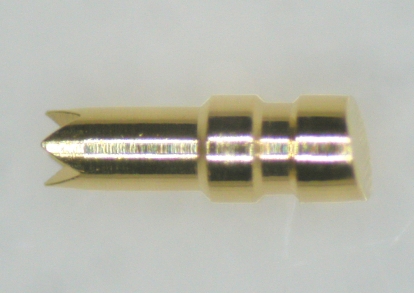

Bias cut plunger

- Materia:

- BeCu

- Purpose of Use:

- Contact probe

By fusing and combining the micro cutting technology and micro measuring technology with more than 120 units of CNC precision automatic lathes, we mainly manufacture and sell rounded micro precision cut items, contact probes and contact probe pins.

BS, BeCu, Pb, SK, SUS303, Pd alloy

CNC Precision Automatic Lathe (120 units)

NC Micro Cutting / Case Study

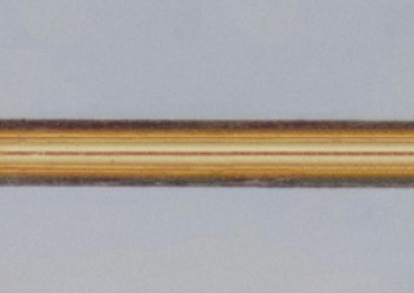

We are able to handle the ultra-fine cutting inφ0.025mm-class, and we can handle mass production as well.

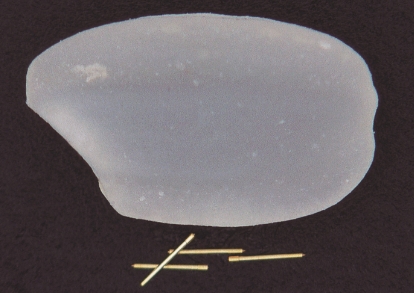

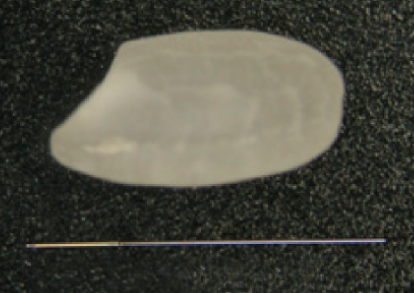

A rice grain and a fabricated component (φ0.05mm).

A rice grain, and two fabricated components, one is φ0.08mm, and the other 6mm in length.

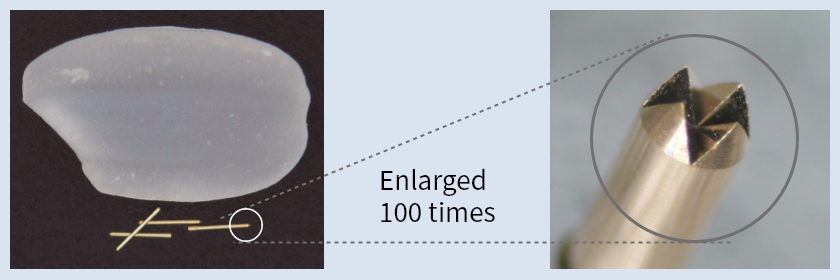

Comparison picture of rice grain (left) and crown fabrication (right).

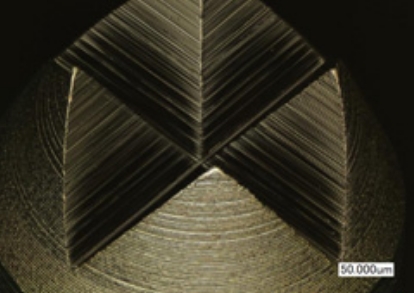

The stability and finesse of our surface finishing are highly reputed.

Surface roughness measurement via laser microscope

Example of a whole finish (bias cut)

| Profile 1 | Ra | Ry | Rz |

|---|---|---|---|

| Whole | 0.04um | 0.48um | 0.29um |

Due to our proprietary fabrication technology, we can reduce the occurrence of burrs.

Fabrication section of crown tip (enlarged)

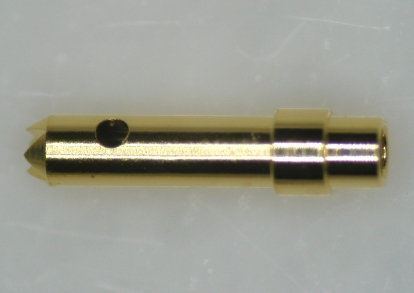

integrated barrel w/ side hole (crown with side hole on back)

Ultra-micro holes (from as small as φ0.09mm in diameter) can be fabricated. Even the inside surface is smooth and clean.

Interior of fabricated hole (enlarged)

Hold diameter 0.06mm, depth 1.0mm

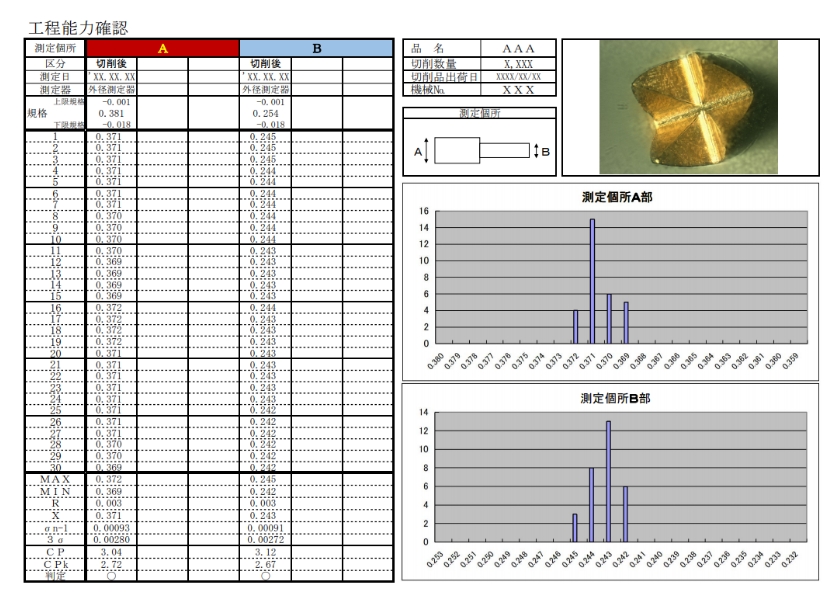

Due to our proprietary process management, we can stabilize the accuracy of the dimensions.

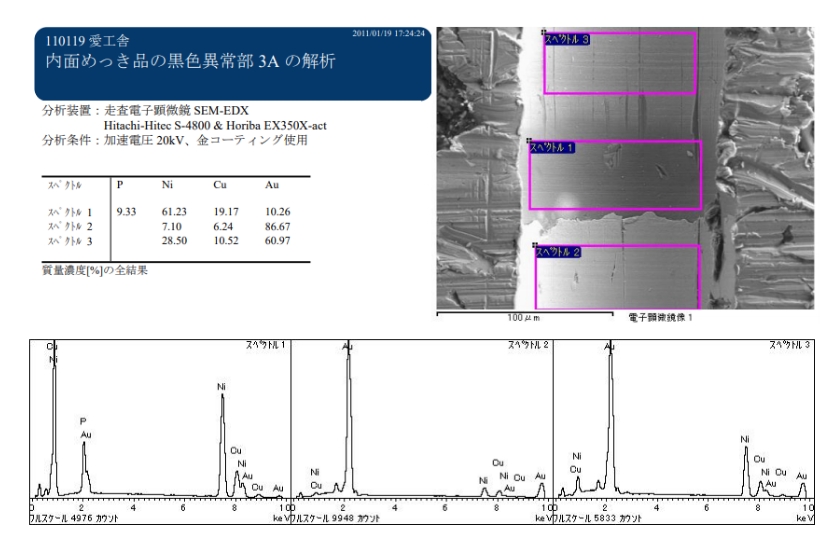

Through our collaborations with partner companies, we offer a thorough quality assurance that is in line with various types of surface processing.

[Example Track Record]

– beryllium copper: aging treatment, SK materials: heat treatment, hard gold plating, palladium cobalt plating, rhodium plating, lubricant gold plating, composite plating

Even after delivery, we are able to provide support through submission of various documentations and analysis.

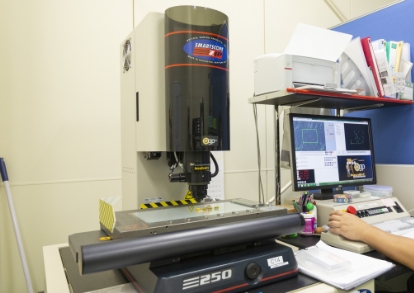

Example of evaluation device: Non-contact all-automated measuring system

Example of analysis device: Laser microscope

Ultra-micro fabrication

Crown fabrication

Plunger Fabrication

Deep hole fabrication

Raising

Multi-screw slotting