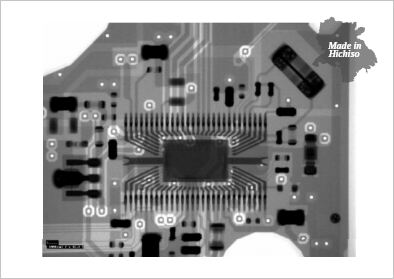

X-ray source:

– Minimum resolution: 0.4μm

– Tube voltage: 20kV to 130kV

– Tube current: up to 200μA

Maximum geometric magnification:

-1200 times (monitor magnification 5760 times)

Stage:

– Size: 400mm in diameter

– Load weight: 5hg

– Stroke (X axis / Y axis): ±200mm/±150mm

– Stroke (Z axis / θ axis): 230mm / 360°

Detector tilt mechanism:

-0 to 60dp

Maximum inspection range:

-335mm x 300mm